DataMatrix and two-dimensional codes: Laser Marking for traceability and quality

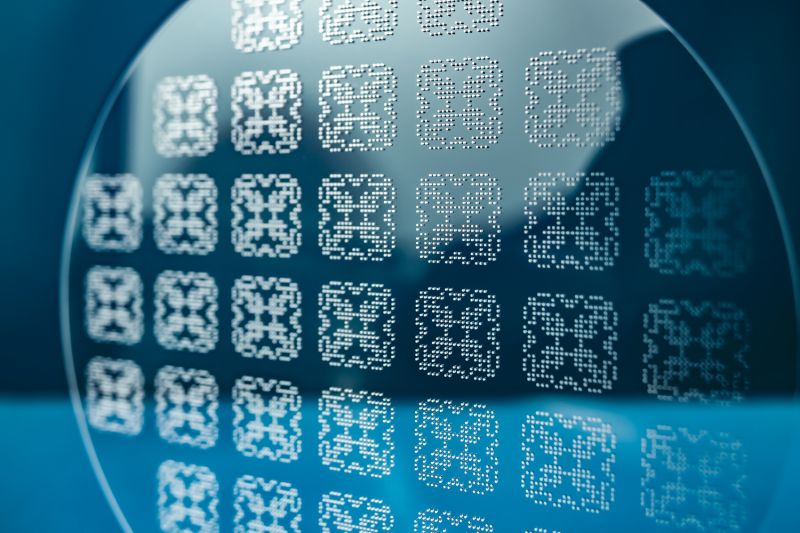

Two-dimensional codes represent the natural evolution of traditional linear barcodes, offering superior data storage capacity in extremely small spaces. Among these, the DataMatrix code stands out as one of the most reliable and versatile formats, particularly valued in industrial applications where precision and durability are essential requirements.

Laser marking of DataMatrix codes has revolutionized numerous sectors, from pharmaceuticals to automotive, ensuring traceability, safety, and compliance with the most rigorous international standards.

What does DataMatrix mean?

The DataMatrix is a two-dimensional barcode made up of a matrix of black and white square cells arranged according to a precise geometric pattern. The name “DataMatrix” comes from its matrix structure, where each individual cell (called a module) can take on two states: black or white, corresponding to binary values 0 and 1.

This structural simplicity hides a sophisticated encoding capability that allows it to store up to 2,335 alphanumeric characters or 3,116 numeric characters in a space as small as 1×1 millimeter.

The peculiarity of the DataMatrix code lies in its high resilience to damage. Thanks to the ECC200 error correction algorithm, the code remains readable even when up to 30% of its surface is compromised.

This feature makes it ideal for industrial applications where components are exposed to significant mechanical, thermal, or chemical stress.

Where can the DataMatrix code be found?

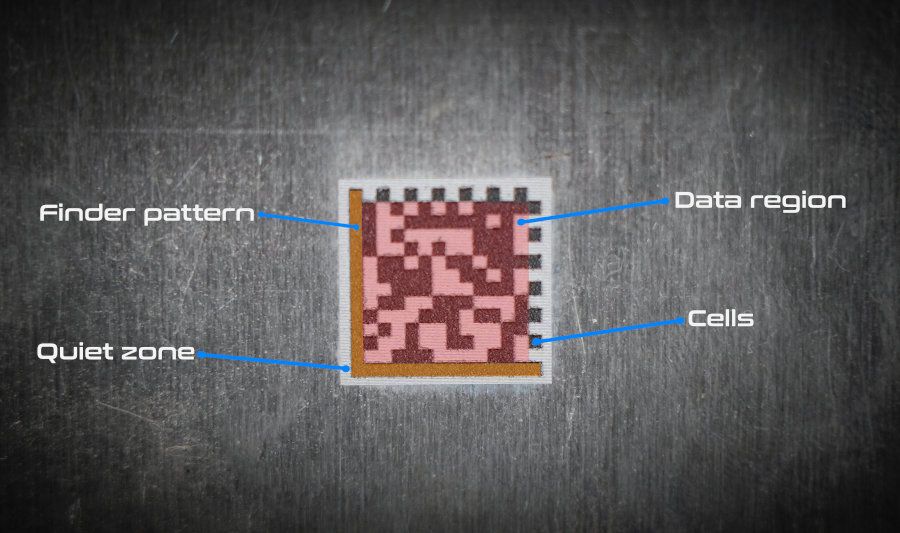

The DataMatrix code appears visually as a square or rectangle composed of small black and white squares. Its identification is facilitated by two distinctive elements: the finder pattern and the timing pattern.

The finder pattern consists of a solid black line outlining two adjacent sides of the code (typically the left and bottom sides), forming an inverted “L.” This pattern allows optical readers to properly orient the code regardless of its position or rotation.

On the opposite sides of the finder pattern lies the timing pattern, made up of an alternating sequence of black and white modules that define the modular structure of the code. These identification elements are essential for automatic decoding and represent the signature feature that distinguishes DataMatrix from other two-dimensional codes such as the QR Code.

The placement of DataMatrix codes varies significantly depending on the specific application:

- In the automotive industry, they are commonly engraved on aluminum die-cast parts, engine components, and critical chassis parts.

- In the pharmaceutical sector, they appear on medicine packaging as part of mandatory traceability systems.

- In the aerospace sector, they are applied to structural, electronic, and mechanical components to ensure full lifecycle traceability.

How to read a DataMatrix code

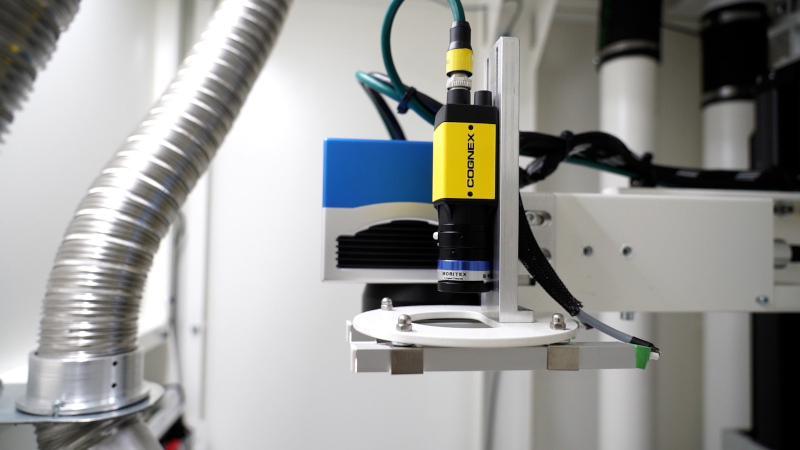

Reading a DataMatrix code requires special devices equipped with two-dimensional imaging technology. Traditional barcode readers, designed for linear codes, cannot decode these two-dimensional symbols.

Modern reading systems use CCD or CMOS sensors that capture a complete image of the code, which is then processed through advanced shape recognition algorithms.

The decoding process follows a precise sequence of operations:

- The software first locates the finder pattern to determine the code’s orientation.

- Next, it identifies the timing pattern to establish the matrix dimensions and the exact position of each module.

- Finally, the algorithm reads the data modules following a predefined spiral pattern while simultaneously applying ECC200 error correction to ensure decoding accuracy.

The reading quality is evaluated according to standardized parameters including contrast, modulation, decodability, and distortion.

These parameters are crucial to determine the quality grade of the code, expressed on a scale from A (excellent) to F (poor), according to international standards.

What does a DataMatrix code contain?

The internal structure of the DataMatrix code follows a precise hierarchical organization that maximizes storage efficiency and reading robustness.

The quiet zone represents the white area surrounding the code, essential to provide adequate contrast with the background and to facilitate automatic identification. This zone must maintain a minimum width equal to one module on all sides of the code.

The finder pattern and timing pattern, already described above, serve as the geometric reference elements of the code. The data region occupies the central area and actually contains the encoded information. Within this region, the data is arranged in a logical sequence that begins at the upper right corner and proceeds counterclockwise in a spiral toward the center.

The modules represent the fundamental unit of information in the code. Each module can be white (0) or black (1), and their geometric arrangement follows precise rules that enable automatic error correction. The physical size of the modules determines the resolution of the code and directly influences its readability.

Smaller modules allow for more compact codes but require high-resolution reading systems.

Larger modules offer greater tolerance to printing errors but occupy more space.

Laser Marking DataMatrix: Technologies and Industrial Applications

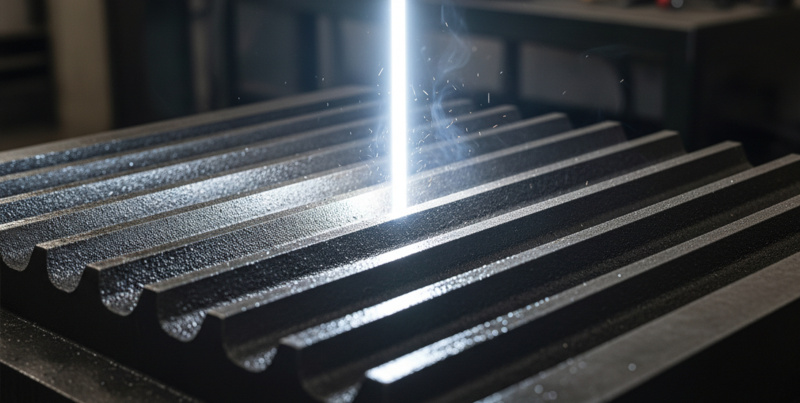

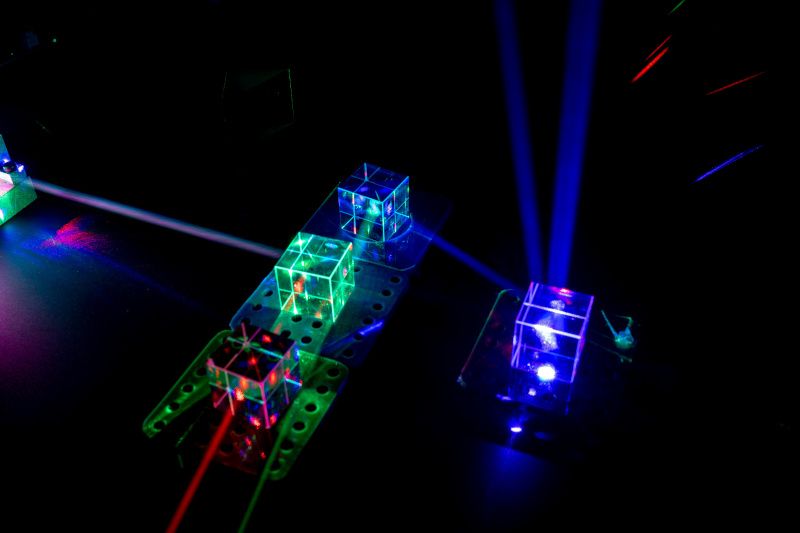

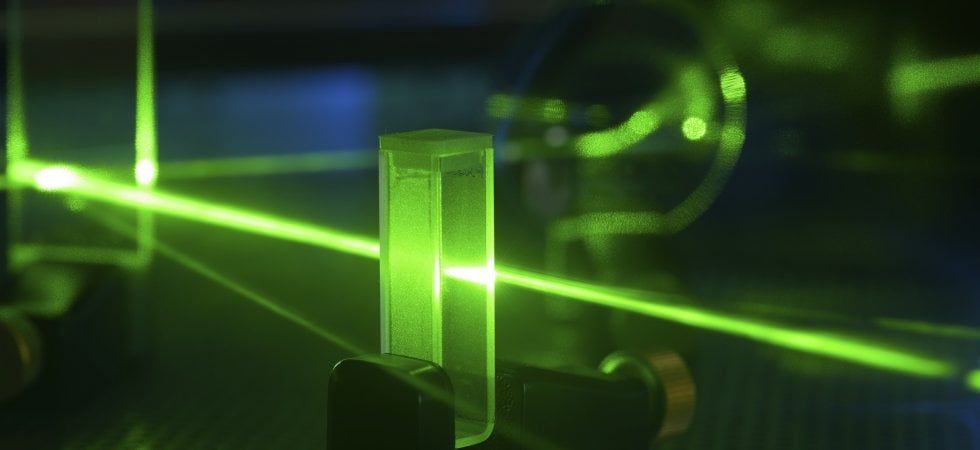

Laser marking represents the most advanced and reliable technology for producing permanent DataMatrix codes on a wide range of materials. This technique uses the energy of a laser beam to locally modify the surface properties of the substrate, creating stable and durable optical contrasts. The micrometric precision of laser systems allows the production of extremely small DataMatrix codes while maintaining high quality standards.

Aluminum die-cast parts are among the most common substrates for laser marking DataMatrix codes in industrial applications. Aluminum offers excellent laser absorption properties, enabling high-contrast markings with reduced processing times.

The surface of die-cast parts, often characterized by controlled roughness, enhances code definition and improves readability even in harsh environments. In the automotive and aerospace sectors, this combination of material and technology ensures permanent traceability of critical components exposed to high thermal and mechanical stress.

Materials and Reverse mode

Steel is another material frequently used for laser marking DataMatrix, especially in applications where corrosion resistance and structural integrity are priorities. Laser parameters must be specifically optimized for each type of steel, considering chemical composition, heat treatment, and surface finish. Stainless steels require higher energy but yield extremely durable and chemically resistant markings.

The reverse mode is a technical variant of laser marking in which the contrast is inverted: areas normally black become white and vice versa.

This technique is particularly useful on dark materials or when a specific aesthetic effect is desired. Reverse marking requires precisely calibrated laser parameters to ensure adequate contrast and optimal readability.

Laser Marking Machines

See Evlaser productsStandards and Regulations

International standards strictly govern the production and verification of laser-marked DataMatrix codes.

ISO/IEC 16022 (ECC200) defines the technical specifications of the DataMatrix symbol, including modular structure, encoding algorithms, and error correction mechanisms.

ISO/IEC 15415 establishes the quality assessment parameters for two-dimensional codes, providing standardized methodologies to measure contrast, modulation, decodability, and other critical parameters.

ISO/IEC 15434 and ISO/IEC 15418 respectively regulate data syntax and automatic identification, ensuring interoperability across different systems.

Reference industries

In the healthcare and pharmaceutical sector, laser-marked DataMatrix codes play a crucial role in traceability and anti-counterfeiting. The European FMD (Falsified Medicines Directive) requires the use of GS1 DataMatrix on every pharmaceutical package, containing essential information such as batch number, expiration date, serial number, and product code. Laser marking ensures the permanence and immutability of this data, essential for patient safety and the fight against counterfeiting.

The aerospace and defense industry uses laser marking on DataMatrix codes for the complete traceability of critical components throughout their lifecycle. Each piece, from production to decommissioning, maintains a unique digital identity that allows reconstruction of its full history: materials used, manufacturing processes, passed tests, maintenance interventions, and placement in the final assembly. This traceability is essential for operational safety and predictive maintenance management.

In the logistics and retail sector, DataMatrix codes facilitate warehouse automation and inventory management. Their ability to store detailed information in small spaces makes them ideal for labeling small products or for applications where space is limited. The robustness of laser marking ensures readability even after intensive handling and transport in harsh conditions.

The automotive industry is probably the sector with the widest use of laser-marked DataMatrix codes. Component traceability is fundamental for recall management, scheduled maintenance, and anti-counterfeiting of spare parts. Every component, from the smallest sensor to the engine block, can be uniquely identified through its DataMatrix code, enabling precise supply chain management and data-driven maintenance.

Laser-marked DataMatrix codes therefore represent a mature and indispensable technology for numerous industrial sectors, offering reliable solutions for traceability, safety, and regulatory compliance.

The continuous evolution of laser technologies and quality control systems promises further improvements in speed, precision, and application versatility, consolidating the central role of this technology in modern production processes.