- Home

- >

- Products

- >

- Laser Engraving

- >

- Roboplate

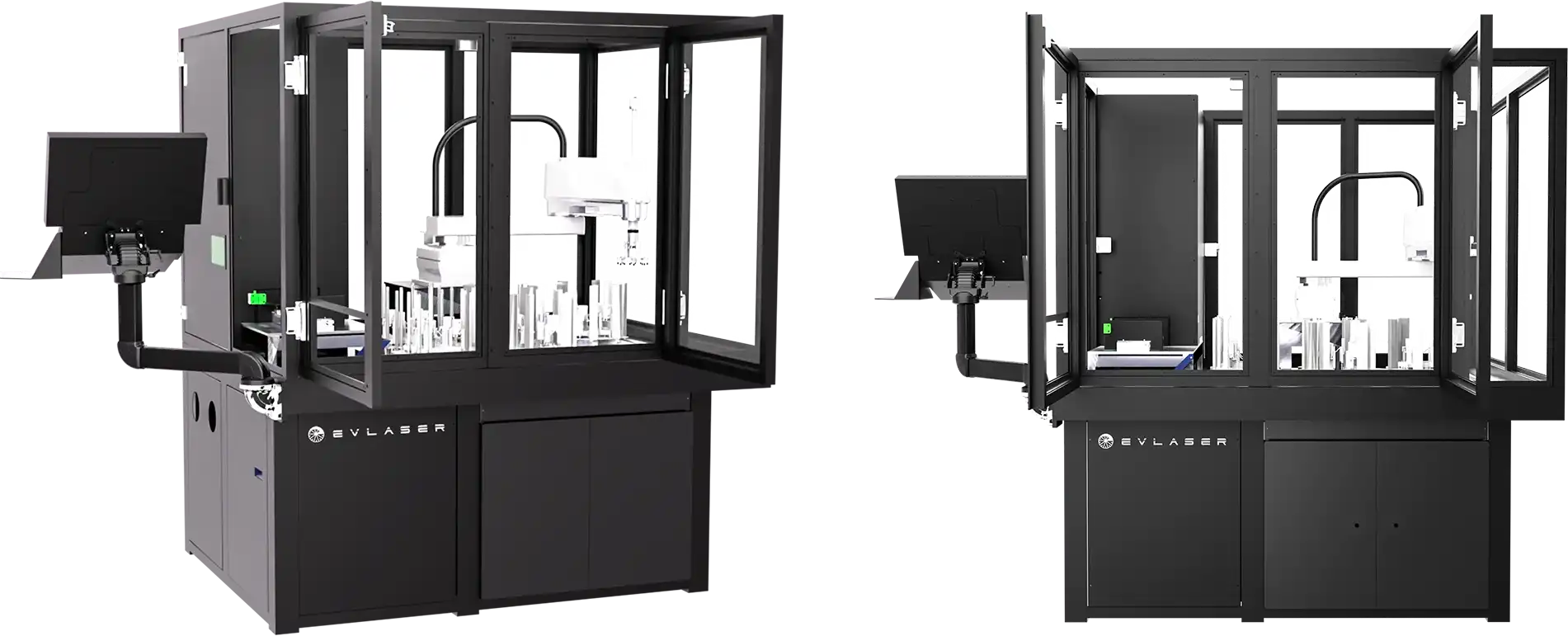

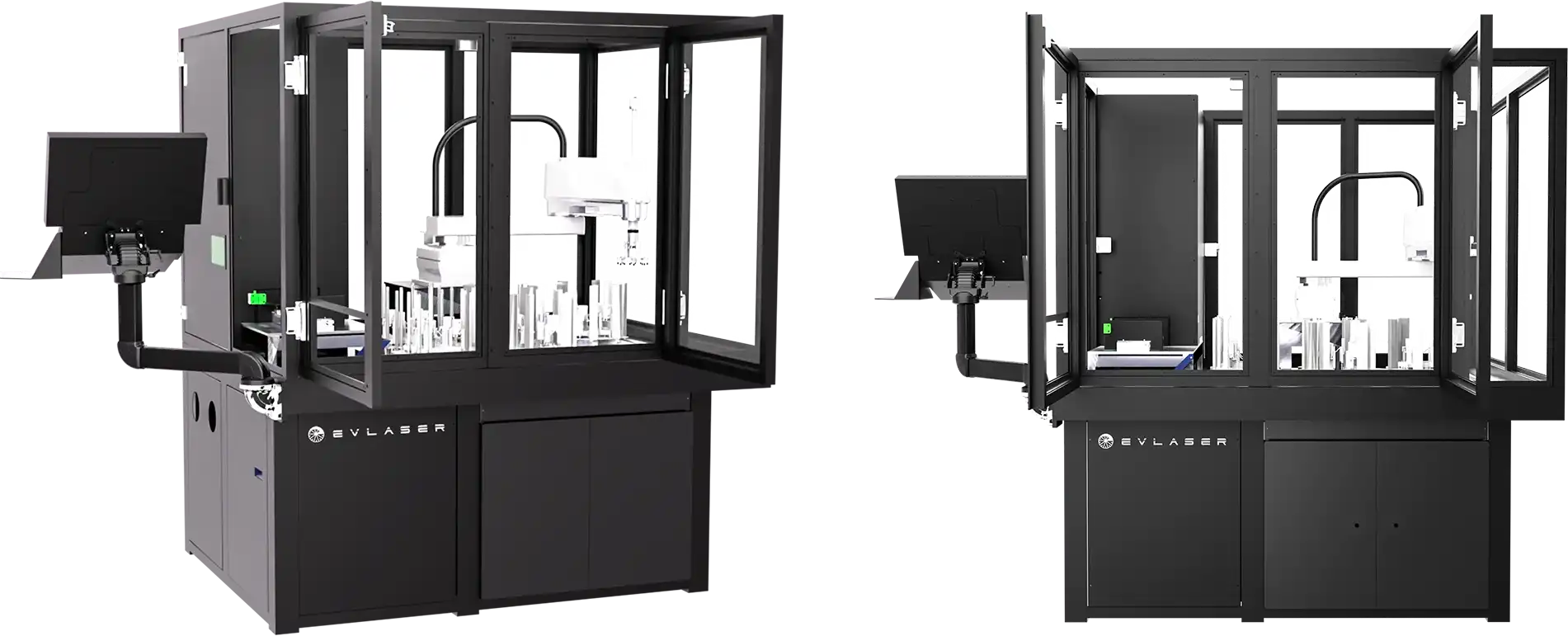

Roboplate

ROBOPLATE is EVLASER’s industrial laser marking machine dedicated to automatic nameplate marking, designed to ensure productivity, precision and operational continuity. It is a complete and autonomous solution, ideal for high-volume industrial environments.

Equipped with a robotic system, it automatically manages the loading, marking and unloading cycle of nameplates. The Pick & Place retrieval system ensures fast and accurate positioning, while the multiple loading magazines allow for high working autonomy. The final random unloading allows maximum flexibility in integration with downstream processes.

ROBOPLATE is designed to be easily integrated into automatic lines and robotic islands, offering high reliability, complete process control and simple, intuitive management.

Fill out the form and you will receive the complete technical sheet

AUTOMATION

Complete cycle of loading, marking and unloading managed by pick&place robotic system

PRODUCTIVITY

Multiple magazines and continuous operation for high-volume industrial applications

RELIABILITY

Positioning precision and total process control for consistent results over time

Technical specifics

| Laser | Fibra Yb | DPSS Nd:Yag | DPSS Nd:Yag | CO2 |

| Technology | Qswitch / MOPA /CW / QCW | Qswitch | Qswitch | RF |

| Wavelenght | 1064nvm | 532nm (GREEN) | 355nm (UV) | 10600nm |

| Power | 20 TO 200W | 5 TO 10W | 3 TO 10W | 10 / 30 / 60 / 100W |

| Galvohead | 2D / 3D (OPZ.) | 2D / 3D (OPZ.) | 2D / 3D (OPZ.) | 2D / 3D (OPZ.) |

| Vision system | optional | optional | optional | optional |

| Safety class | 4 ACCORDING TO EN 60825-1: 2014 | 4 ACCORDING TO EN 60825-1: 2014 | 4 ACCORDING TO EN 60825-1: 2014 | 4 ACCORDING TO EN 60825-1: 2014 |

THE BEST LASER SOLUTIONS FOR YOUR REQUIREMENTS

Fill out the form to discover how our industrial laser systems can optimize your production and improve work quality.

How can we help you?

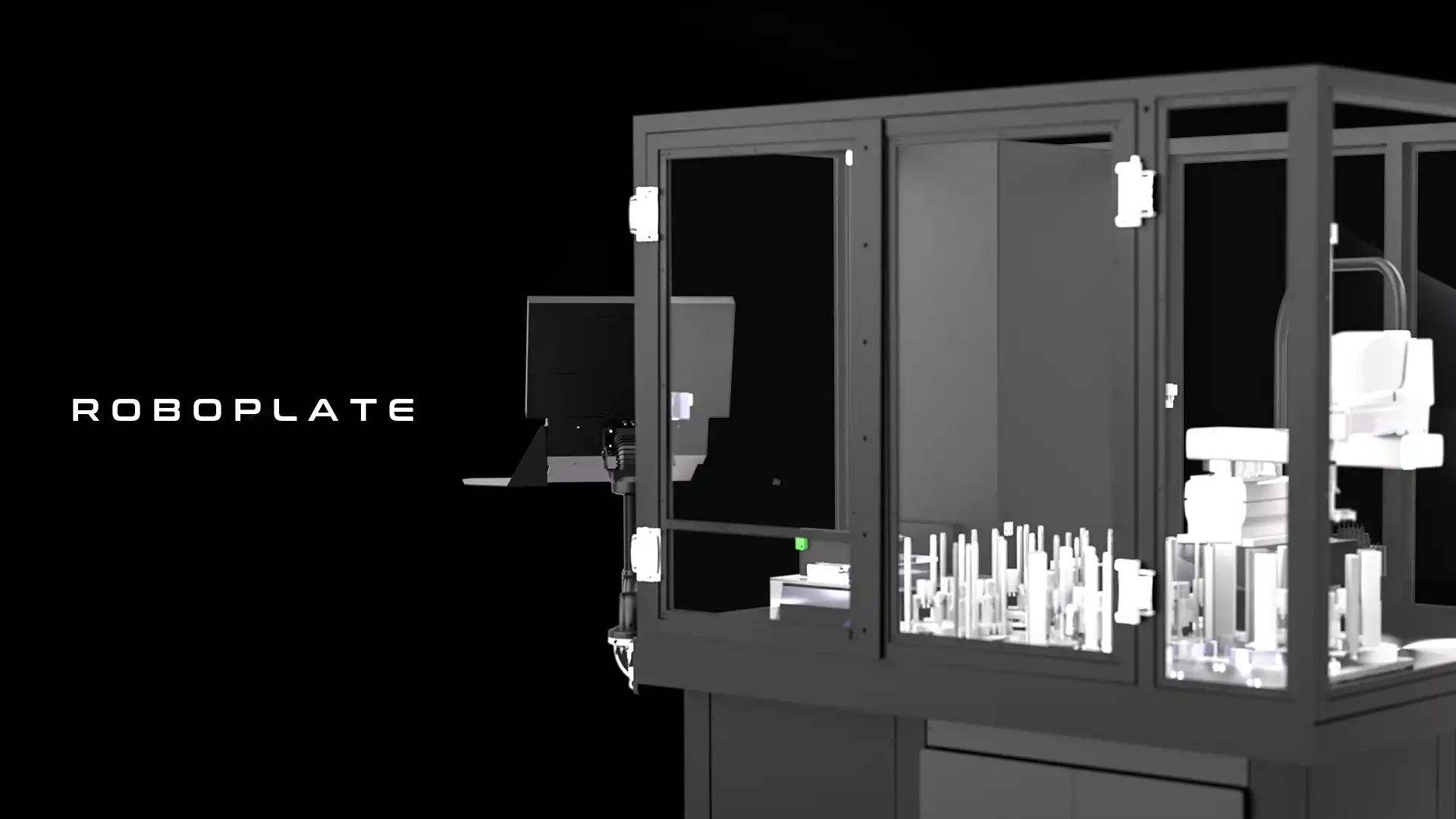

Matrix – Software Suite

Matrix is an advanced Software Suite developed thanks to thirty years of experience in Laser Marking, Engraving, Welding and Micromachining systems and ready for the challenges of Industry 4.0. It represents the state of the art of work functions and has the best man-machine interface on the market. This makes the training times of the operators practically nil and makes even more intense use pleasant. The practical EASYPAD touch on the front of the machine allows the operator to control the primary functions of MATRIX even without accessing the PC, allowing for a reduction in working times and making it easier to use.

ERP-MES

Integrated management of traceability thanks to the possible interfacing with management software, ERP, MES or database and to the reading and verification functions of texts or 1D / 2D codes through the integrated vision system.

Add-on Packages

Modularity-oriented development allows the customer to configure MATRIX according to their needs. New needs will be easily addressed thanks to the packages and customizations that can be installed even after purchase using the convenient “LIVESERVICE” remote connection tool.

Smart Factory Ready

The Smart 4.0 package allows you to have remote control and monitoring of the system, with Reporting and Analytics on the productivity and quality of the work center and with the management of all the connections necessary for the factory interconnection.

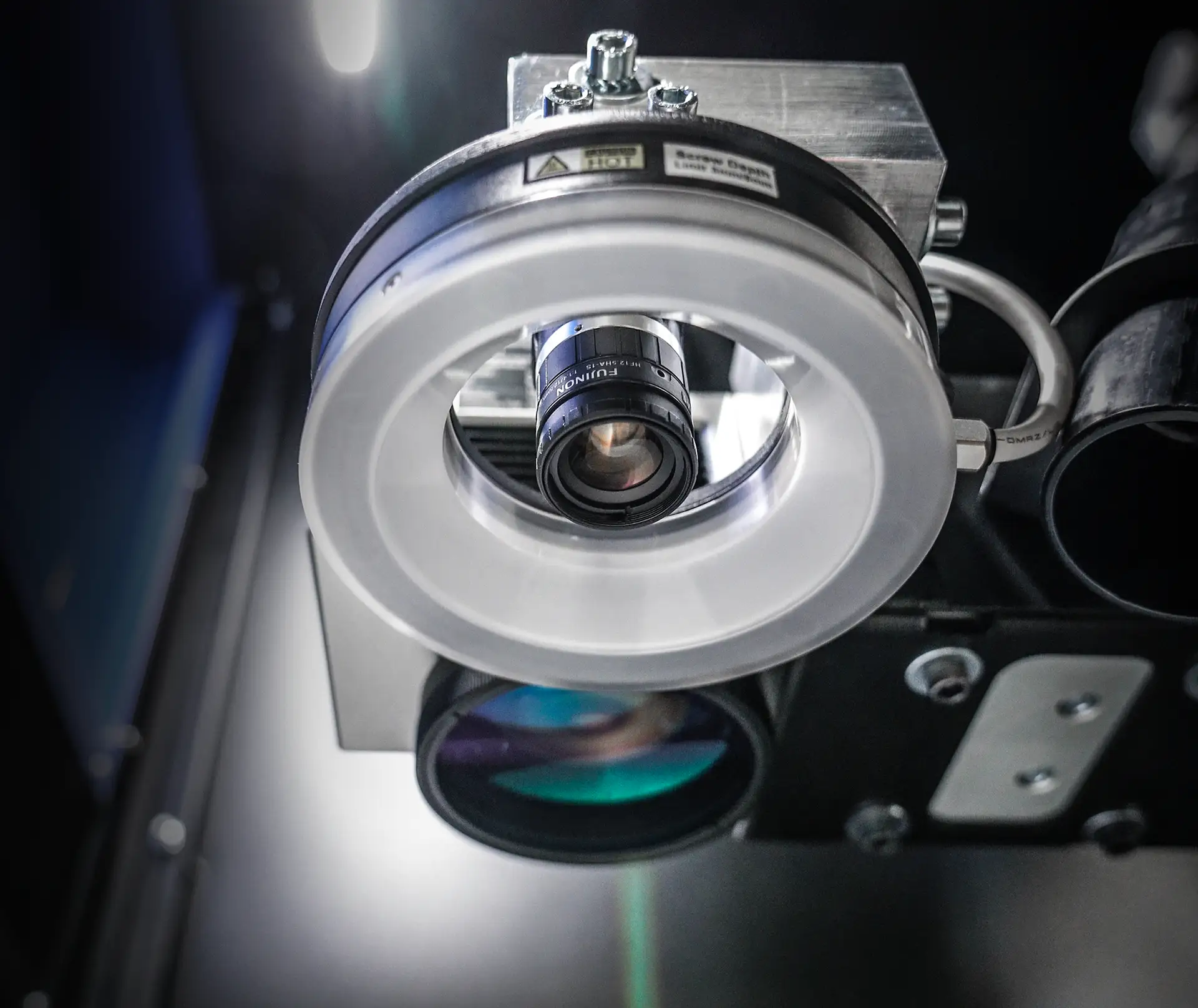

Vision Systems

Advanced Vision Devices (AVD), are a fundamental part of our offer, as they integrate into complex systems designed for the various application sectors. The use of recognition algorithms, neural networks and artificial intelligence makes the field of use and potential extremely extensive. The native integration of vision features with MATRIX software programming allows unparalleled flexibility in the management of production processes.

Pattern Matching

“PATTERN MATCHING” function for automatic recognition of the position of the piece and consequent automatic alignment of the machining.”PATTERN MATCHING” function for automatic recognition of the position of the piece and consequent automatic alignment of the machining.

Quality Inspection

“QUALITY INSPECTION” function for the recognition of attributes on the piece (color, shape, size, presence or absence of artefacts, surface finish, etc.), with the assignment of a Pass / Fail or a Class of Membership.

OCR – Barcode 1D/2D

Functionality of reading and verification of texts (OCR) or 1D / 2D codes (barcode, datamatrix, QR code, etc.) integrated with the software to fulfill the traceability needs of the process or to guarantee the quality and the result in the case of a marking.