Laser Decoating: precision and innovation for Industry

The removal of paint and coatings from metal surfaces has always represented a challenge for the manufacturing industry. Traditional techniques, based on chemical or mechanical processes, now show clear limitations in terms of precision, environmental impact, and operational safety. Laser Decoating emerges as an innovative solution, capable of meeting the growing quality and sustainability requirements of the industrial sector.

What is Laser Decoating?

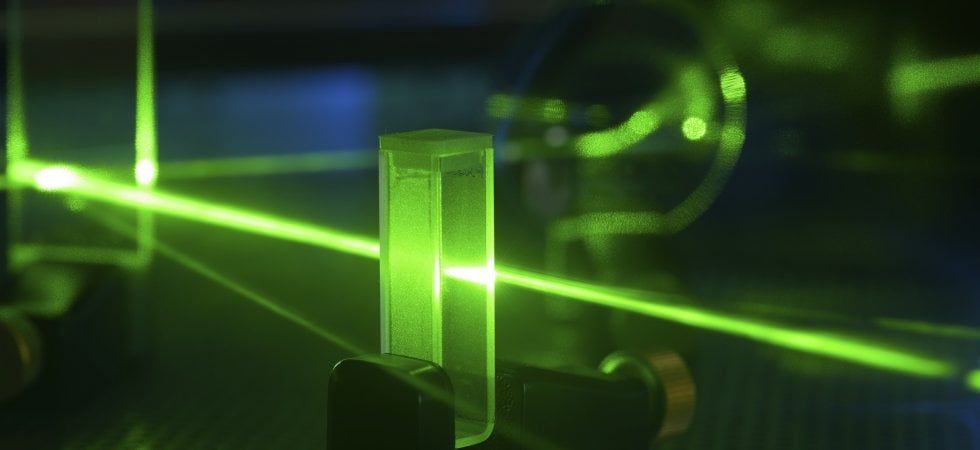

Laser decoating is an advanced industrial process that uses a high-energy light beam to remove paints, coatings, and surface layers from materials without damaging the underlying substrate. Unlike conventional methodologies that employ aggressive chemical substances or abrasive techniques, the decoating laser acts through direct interaction between light radiation and the material to be removed.

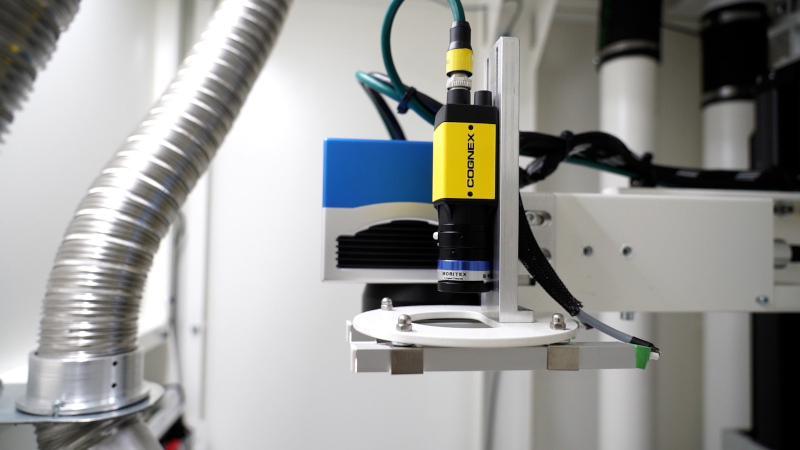

This technology represents a significant evolution in the field of material surface treatment. A modern laser decoater integrates a high-power laser source with computerized control systems that allow extremely precise management of processing parameters. The result is a clean, repeatable, and fully traceable process, fundamental characteristics for high-tech production contexts.

Laser paint removal finds application both in maintenance and restoration operations, where it is necessary to preserve the integrity of the base material, and in industrial production processes, when surfaces need to be prepared for subsequent processing or coatings. The versatility of this technology makes it suitable for both small series and high-volume production.

Laser Cleaning

See Evlaser ProductsHow does Laser Decoating work?

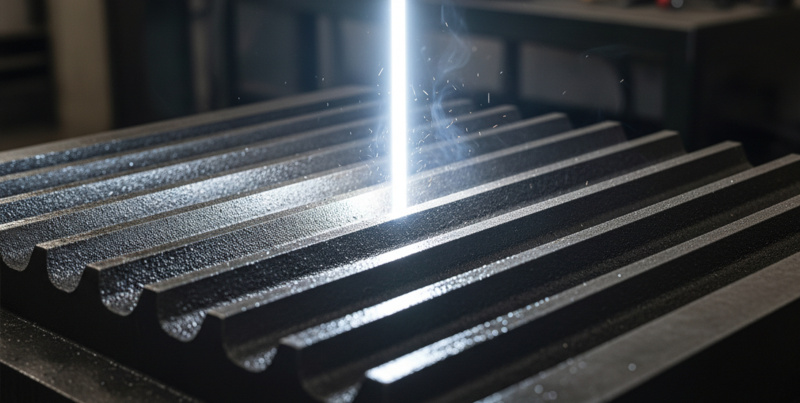

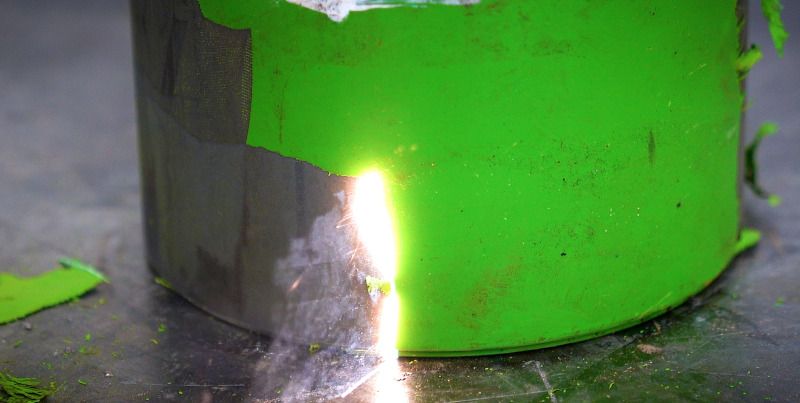

The functioning of laser decoating is based on the principle of photothermal ablation. When the laser beam strikes the painted surface, the light energy is absorbed by the coating layer, causing its instantaneous heating. The speed of this process is such that the paint is literally vaporized before the heat can propagate to the underlying material.

The process unfolds in several phases that occur in fractions of a second. Initially, the laser radiation is absorbed by the paint, which rapidly reaches extremely high temperatures localized in the surface layers. This concentrated energy causes the breaking of molecular bonds in the coating, transforming it into gas and microscopic particles. The underlying metal substrate, having different absorption characteristics, remains practically unaltered.

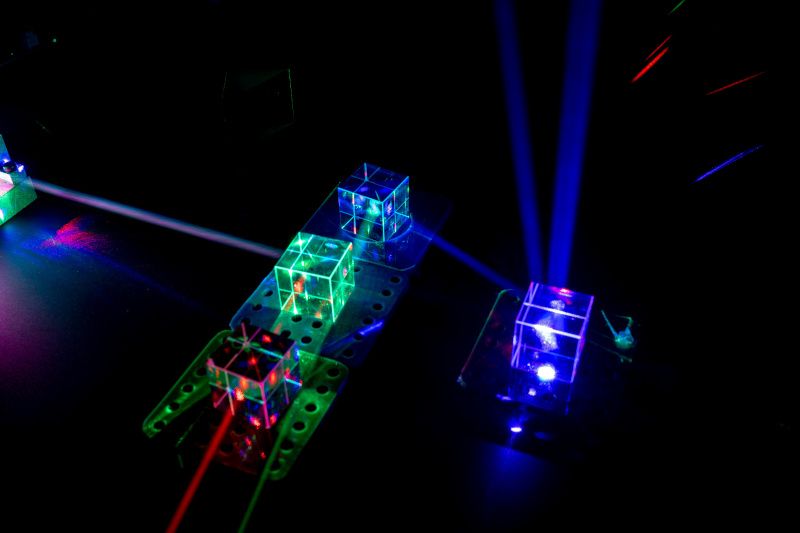

A crucial element is the selectivity of the process. A modern laser decoating machine allows extremely precise adjustment of various operational parameters:

- Laser wavelength: determines the absorption efficiency by the paint compared to the base metal

- Beam power: affects the removal speed and depth of action

- Pulse duration: controls the amount of energy transferred to the material in each cycle

- Scanning speed: defines the area treated per unit of time

- Repetition frequency: optimizes the overall process efficiency

The most advanced systems integrate optical sensors that monitor the decoating progress in real-time, allowing the system to automatically adapt to variations in coating thickness or surface irregularities. This dynamic control guarantees uniform results even on complex geometries or when working with multilayer paints of different composition.

The advantages of Laser Decoating

Laser technology for paint removal offers significant benefits compared to traditional methods, making it a preferred choice for high-quality industrial applications. These advantages concern not only the quality of the final result but involve the entire production process, from operational safety to environmental sustainability.

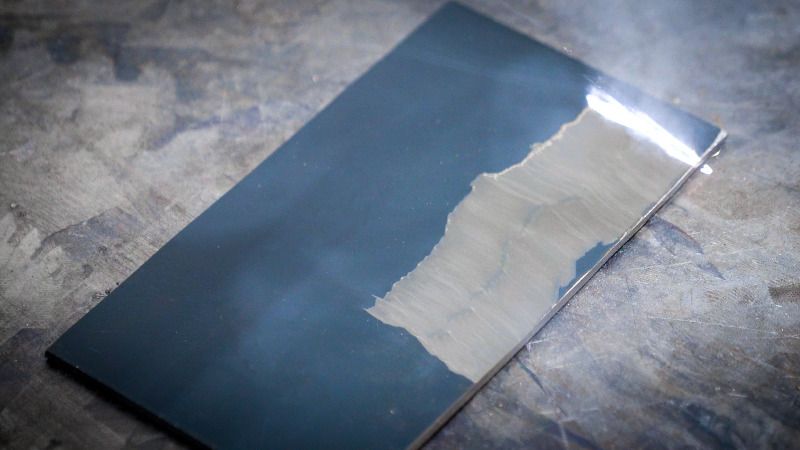

- Preservation of base material: The laser beam does not damage the underlying material thanks to its selective action. While the paint intensely absorbs light energy and is vaporized, the metal substrate reflects most of the radiation or absorbs an insufficient amount to cause alterations. This aspect is particularly critical when working on precision components or valuable parts requiring conservative restoration interventions.

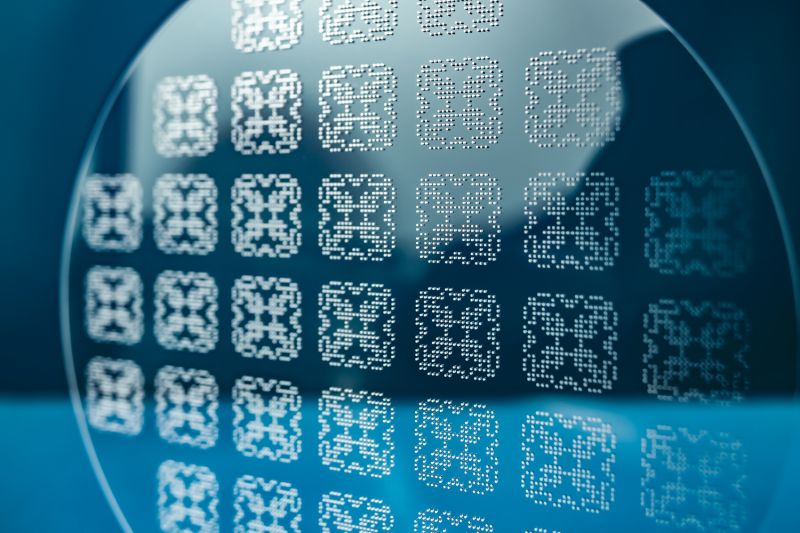

- Precision and accuracy: The laser selectively vaporizes paint with high beam intensity, allowing operation on specific areas without affecting surrounding zones. A laser decoater for iron can work on details of just a few square millimeters while keeping adjacent surfaces intact, a characteristic impossible to achieve with chemical methods or sandblasting. The process is very precise and localized, allowing surgical interventions on complex components.

- Absence of consumables and residues: Unlike sandblasting which requires abrasives or chemical processes that consume solvents, laser decoating does not need consumable materials. No chemical sludge is generated for disposal, no contaminated abrasive residues need to be managed. The only emissions are vapors and fine particulate matter that are easily captured by dedicated extraction systems.

- Repeatability and quality control: Each operation can be programmed and repeated with absolute precision. Process parameters are stored and can be recalled, guaranteeing identical results on different batches. This characteristic is fundamental for processes certified according to international quality standards.

- Operational safety: The elimination of hazardous chemical substances drastically reduces risks for operators. There is no exposure to toxic solvents, acids, or corrosive bases. The process takes place inside protected cabins that prevent exposure to laser radiation and contain gaseous emissions.

- Application flexibility: A single system can treat paints of different nature and thickness simply by modifying software parameters, without the need to change equipment or prepare specific chemical baths. This versatility reduces setup times and allows easy management of the variety typical of modern production.

- Process speed: Although speed depends on the thickness and type of paint, laser decoating is competitive or superior to traditional methods, especially when considering overall times that include preparation, treatment, and final cleaning.

Which materials can It work on?

Laser decoating demonstrates excellent effectiveness on a wide range of materials, making this technology extremely versatile for various industrial applications. The key to success lies in the difference in laser radiation absorption between the coating to be removed and the substrate to be preserved.

Metals represent the main and most established field of application. Steel, in its various alloys, responds optimally to laser treatment: from carbon steel used in industrial structures, to stainless steels employed in the food and chemical sectors, to special steels for tools. The laser decoater for iron finds widespread use in the restoration of mechanical components, surface preparation for welding, and maintenance of metal structures.

Aluminum and its alloys particularly benefit from this technology. Being a relatively soft material, aluminum can suffer deformations or undesired material removal with abrasive methods. The laser removes paint while completely preserving surface integrity, a crucial aspect in aerospace and the automotive industry where aluminum components require rigorous dimensional tolerances.

Copper and copper-based alloys, such as brass and bronze, can be effectively treated. These materials find application in electrical, artistic, and architectural components where laser decoating allows recovery of the natural luster of the metal without altering its surface characteristics.

Beyond metals, there are interesting applications on non-metallic materials:

- Wood: The removal of old or degraded paints from precious wooden surfaces, as in the restoration of antique furniture or architectural elements, can be performed with appropriately calibrated lasers that vaporize the coating while respecting wood fibers

- Technical plastics: Some engineered polymers can be treated to remove surface coatings, although particular attention to parameters is required to avoid melting the base material

- Glass: The removal of films, screen prints, or coatings from glass finds application in the automotive industry and furniture sector

As we have already mentioned above, process compatibility depends on the absorption contrast between coating and substrate. When this contrast is marked, laser decoating offers excellent results. Materials with optical characteristics similar to the coating require specific optimizations of laser parameters.

Target application sectors

Laser decoating has found growing adoption in numerous industrial sectors where process quality, precision, and environmental respect represent essential requirements. Each sector uses this technology to meet specific needs, benefiting from the peculiar characteristics of the laser process.

- Automotive and components: The automotive industry employs laser decoating for the recovery of high-value components, surface preparation for welding, and rework of erroneously painted parts. Engine blocks, cylinder heads, transmission components, and body parts can be treated without risk of damage. Laser precision allows intervention on specific areas while preserving surrounding finishes.

- Aerospace: In this sector, where every component is subject to rigorous technical specifications, laser decoating allows removal of coatings from structural parts while maintaining the mechanical properties of the material unaltered. Process traceability and absence of contaminating residues are requirements that laser fully satisfies. Treatment of light alloys such as aluminum and titanium particularly benefits from the non-abrasive approach.

- Industrial and naval maintenance: The recovery of large metal structures, tanks, pipelines, and ship hulls through removal of degraded paints or surface corrosion represents a rapidly growing application. Portable laser systems allow on-site interventions reducing disassembly and transport costs. The elimination of abrasive dust and chemical residues greatly simplifies operations in confined spaces or on operating plants.

- Electronics and micromechanics: The ability to remove coatings from microscopic areas makes laser ideal for rework of printed circuits and electronic components. Capacitors, connectors, and boards with painting defects can be recovered without damaging conductive traces or soldered components.

- Restoration and cultural heritage: Metal artworks, architectural elements, and historical artifacts require non-invasive conservative interventions. Laser decoating allows removal of modern repainting or degraded layers while preserving original surfaces and noble patinas. The delicate parameters used in this field represent the application excellence of the technology.

- Oil & Gas and petrochemical: Components exposed to corrosive environments, such as valves, flanges, and pipelines, require periodic maintenance operations. Laser decoating guarantees surface preparations compliant with international standards for subsequent protective coatings, eliminating risks associated with solvents in potentially explosive environments.

- Tools and molds: The sector of plastic and die-casting molds benefits from the possibility of periodically renewing work surfaces by removing material accumulations and degraded coatings. The dimensional precision of molds is preserved, an aspect impossible to guarantee with abrasive methods that inevitably erode the base material.

The diffusion of laser technology for decoating continues to expand as industries recognize the competitive advantages offered: superior quality, reduced environmental impact, greater operational safety, and process flexibility. In a market that demands increasingly high quality standards and certified environmental sustainability, laser decoating positions itself as an enabling technology for the industry of the future.