What is Laser Engraving and how does it work?

Laser engraving is based on the principle of using a laser beam to modify the surface characteristics of materials by locally vaporizing and removing material (laser ablation). The beam passes multiple times over the surface to create cavities with well-defined geometric properties (edges, fillets, surface finish of the engraving, etc.).

To direct the beam during processing, a laser head equipped with two or more mirror galvanometers is used, which directs the laser beam during operations with extremely high speed and precision.

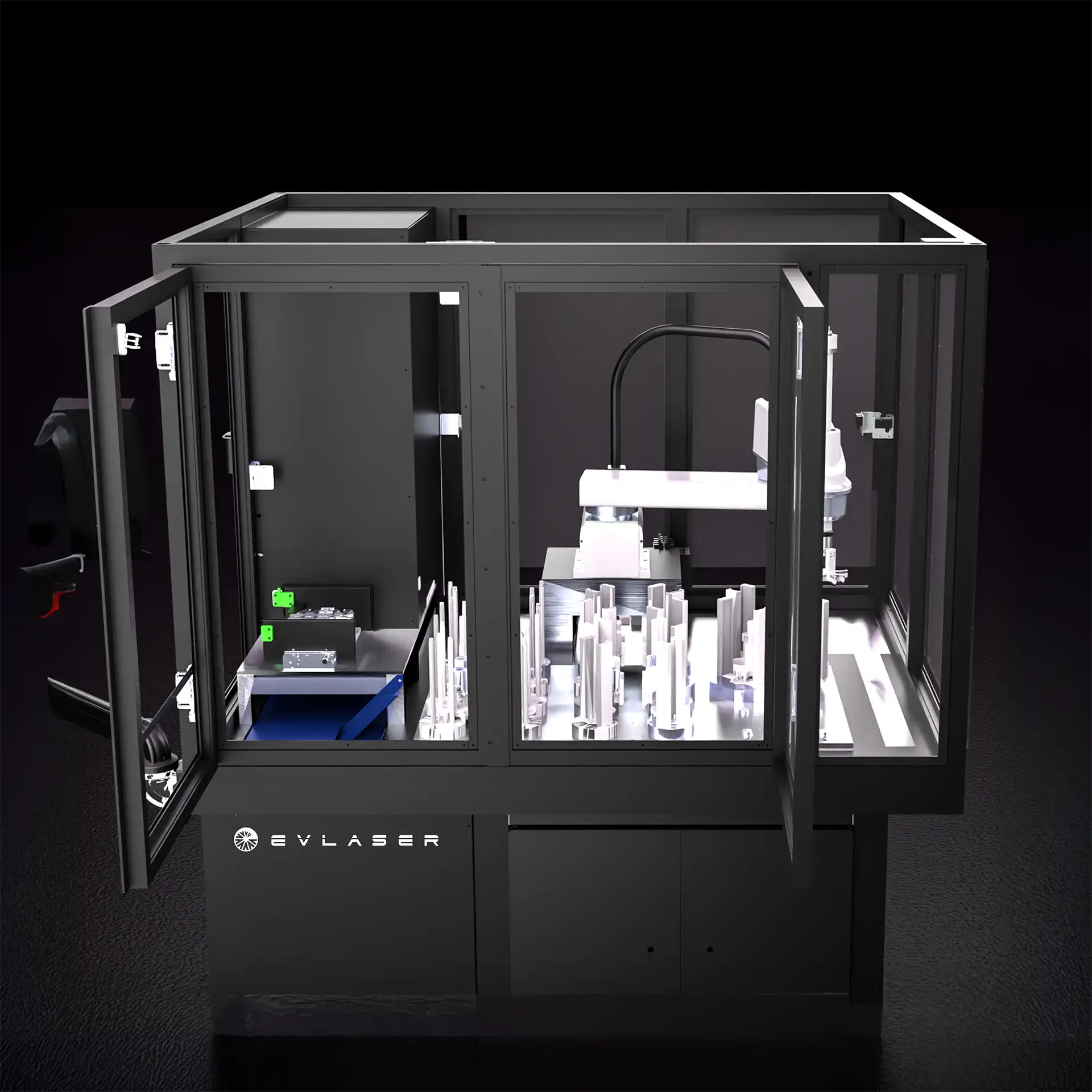

Why choose EVLaser?

01

Decades of experience

02

Strategic geographic location

03

Reliability and technical support

04

Industrial quality at competitive prices

LASER ENGRAVING

Laser engraving is used in various industrial sectors, such as jewelry, mechanical component manufacturing, and art object decoration. Furthermore, this technology is becoming increasingly popular among private users, who use laser engraving to personalize objects such as smartphones, tablets, keychains, and bracelets.

The flexibility and precision of processing that can be achieved with a laser engraver are superior to any other mechanical or chemical processing method available.

FAST AND EFFICIENT TECHNICAL SUPPORT

Our specialized team of Service Engineers guarantees comprehensive support for all your needs. We offer

THE BEST LASER SOLUTIONS FOR YOUR REQUIREMENTS

Fill out the form to discover how our industrial laser systems can optimize your production and improve work quality.

How can we help you?

If you haven't found what you were looking for, try discovering other applications

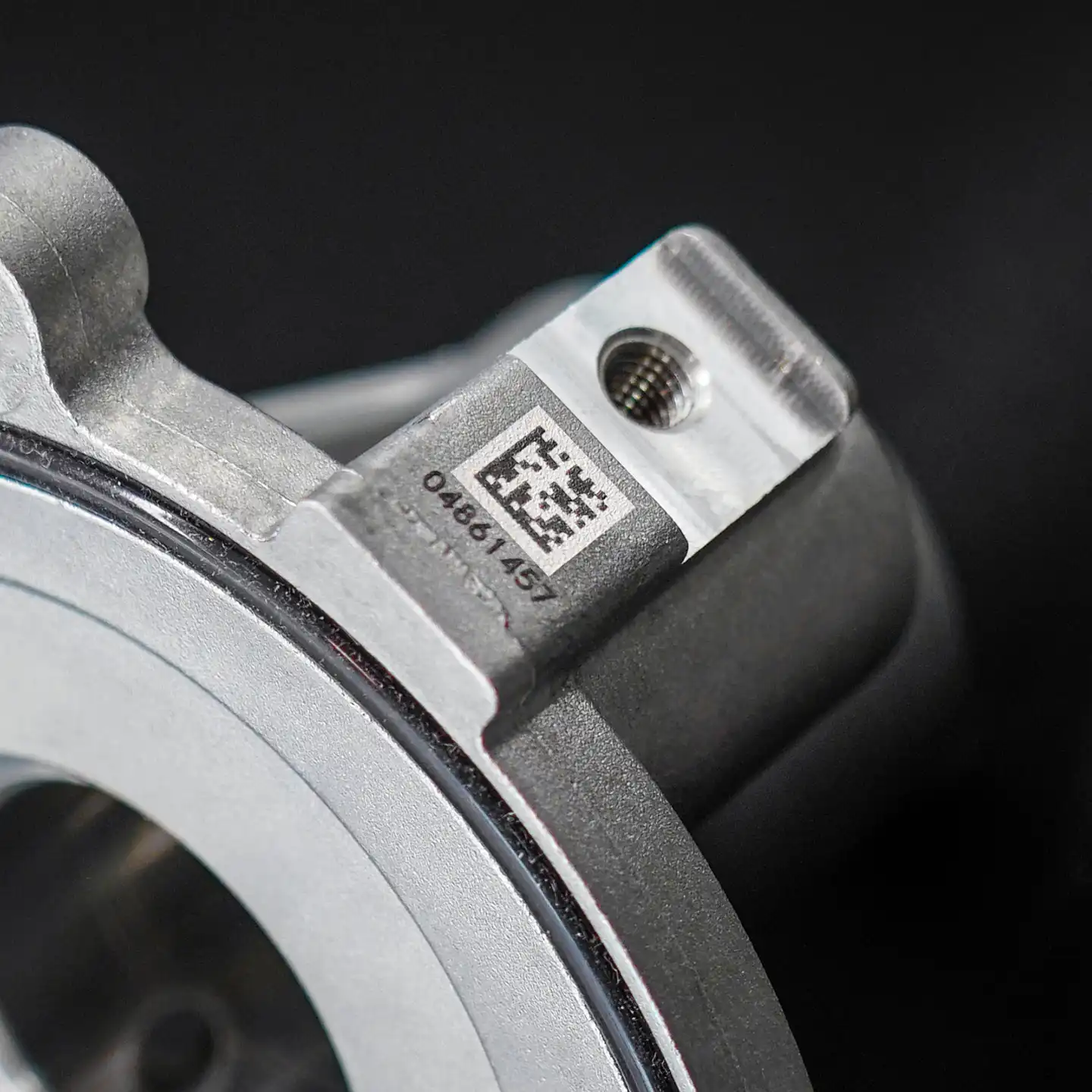

MARKING

Laser marking technology, combined with advanced control systems, guarantees clear and durable identifications on different types of components and materials.

MICROMACHINING

Laser micromachining allows precision customization on a microscopic scale, ideal for creating complex and detailed components.

Laser Engraving applications

Deep Laser Engraving

This technique is used in the construction of tools, moulds, in the identification of chassis in the automotive or in the jewellery.

It consists of incision deeply (up to a few millimetres) into the material, using a multi-pass ablation strategy.

Black Laser Engraving

In this case, Laser Engraving exploits the chemical process of oxidation of the molten material on the surface which occurs thanks to the presence of oxygen.

The surface roughness absorbs a lot of light and gives the effect of black or grayish-brown engravings on specific materials such as (aluminium, copper, brass, etc.).

White laser engraving

White engraving is a shallower process that creates smooth and highly reflective surfaces. In this process the fusion of the material is limited and it adapts perfectly to dark metals such as galvanized steel, hardened steel, etc.

The sectors of greatest interest for Laser Engravers are many, including: mechanics in general, automotive, moulds, tools, medical, jewellery, watches, etc.

Laser cleaning

A particular incision is that of Laser Cleaning, which through the removal of a surface layer of material, is used for pre-processing operations of materials (for example for the removal of oxides on metals) or finishing at the end of the processing cycle ( for example for the removal of chips or particles).

The sectors of greatest interest for Laser Cleaning applications are: mechanics in general, moulds, medical, printing and packaging, etc.

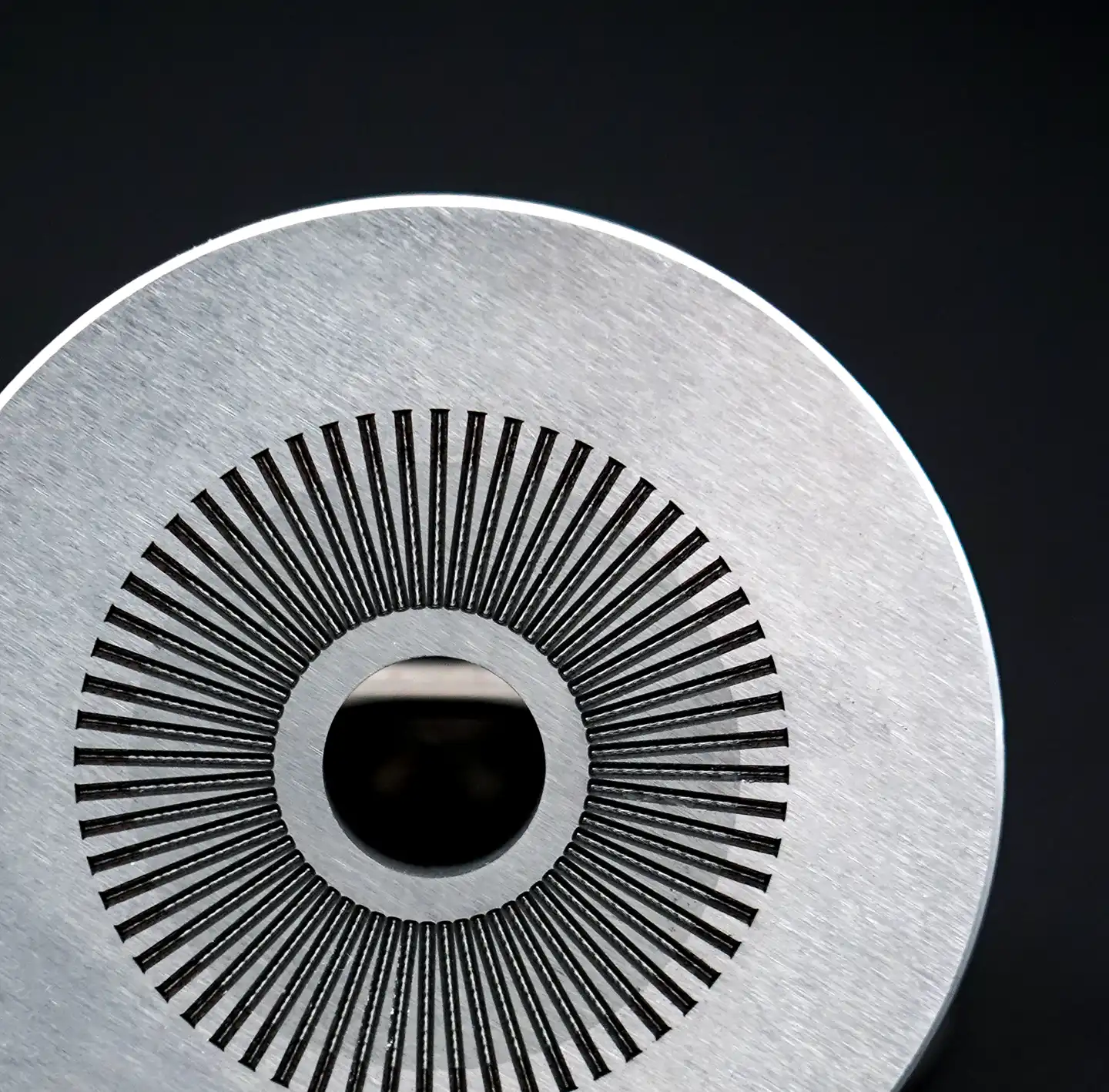

Micro Laser Engravings

Laser micro ablations are used to create laser micro engravings on the material and create patterns or simply excavations of any geometric nature.

Sometimes these processes have a functional purpose and are used to change the surface characteristics of the material (wettability, water repellency, etc.).

An important application related to micro ablation is the removal of thin film deposited on the substrate, which has wide application for the electronic and semiconductor sectors.

Find out more about Laser Cleaning

Discover Laser CleaningLaser Engraving - Usable Materials

Metal

Laser engraving of metals is one of the most widespread applications in the mechanical sector. The excellent results obtainable in terms of contrast and sharpness of the processing, accuracy of the engravings (which can reach the micron in the most demanding applications) and the possibility of leaving the nature of the metal almost unchanged, make the Laser the optimal choice for most of the applications.

The engraving processes also have characteristics of great resistance over time and allow to avoid corrosion phenomena.

Metals suitable for laser engraving are:

- Stainless steel

- Special steels

- Aluminum

- Anodized aluminum

- Titanium

- Brass

- Copper

- Silver

- Gold

- Hardened metals

- Others

Plastic

Plastics are now fundamental in the creation of all sorts of products and it is therefore a need to be able to use the laser for product traceability, or to engrave logos and writings. Plastics change their compatibility characteristics with laser radiation in an important way between the various families and types. This characteristic requires a careful choice of sources and technological solutions to be adopted.

The plastics that can be used for laser engraving are:

- Polyamide (PA)

- Polycarbonate (PC)

- Polyethylene (PE)

- Polyethylene terephthalate (PET)

- Acrylonitrile-butadiene-styrene (ABS)

- Polypropylene (PP)

- PCB

- Mylar

- Silicone

- Others

Glass and ceramic

The processing of glass and ceramics is one of the most challenging due to the brittleness problems of the material and the normal insulation behavior it has with respect to heat sources. For many applications, lasers have replaced mechanical machining as the lack of a contact tool avoids waste related to cracks and fissures. Furthermore, even the maintenance costs of the tools are eliminated and the process times are much lower than traditional processes.

Furthermore, ceramic is a material increasingly used for electronics and sensor applications that require micromachining and that the laser can tackle with excellent results, challenging the fragility related to the various degrees of hardness of the material.

There are various sources for glass and ceramic processing, some examples are CO2 sources and UV sources, but more and more there is the use of ultra-short pulse sources (USP), which with the high peak energies of the pulses are able to accurately and quickly cut and engrave the hard surface. There are also special process measures, such as the adoption of specific spot formers that are able to limit thermal shocks and therefore allow the process speed to increase without creating waste and defects.

Organic (Wood, Leather)

Wood is an important material used for its versatility and wide availability. working with this material with the laser is simple and practical and it is possible to easily engrave both woods of all kinds (including painted ones), to create handicrafts, souvenirs, plates, pieces of furniture, toys, etc. The result that can be obtained is a clean and homogeneous engraving that cannot be obtained with other woodworking methods.

Leather and hide are resistant and rigid materials, difficult for traditional processing. The laser engraving of the leather produces a sharp contrast on the surface, with a tendency to embossing. A greater contrast is obtained with the incisions on darker skin, less in the case of fair skin. The results obtained depend on the type of skin, the laser being used, and the setting of the power, speed and frequency parameters.

Composite fibers

Composite materials are formed by combining several materials with different properties to obtain a new material with different properties and usually superior to the starting ones. Generally a matrix material is used to which a fiber is then added. The most common laser-machinable composites are fiber reinforced polymer composites (FRP), metal matrix composites (MMC) and ceramic matrix composites (CMC). The laser can be used with these materials to successfully engrave and cut the surface by creating shapes, holes and engravings.

Why prefer a Laser Engraver to other technologies

Laser engraving compared to other technologies offers important advantages which must be considered in the selection phase:

Non-contact processing

Laser engravers allow you not to use parts in contact with the piece, being for this reason ideal for materials or products that require careful processing. Furthermore, since there are no contact tools, there are no related wear and maintenance costs.

Respect for nature (Green)

The engraving process is ecological and does not use inks and chemical materials which must then be disposed of.

Modern laser engravers consume less than a home appliance and certainly much less than many of the competing technologies, thus emitting less CO2 into the environment and being more respectful of nature.

Quality and precision of workmanship

Laser engraving are characterized by the quality and precision of the workmanship, as they exploit beams that can reach a few tens of microns. The details, the high contrasts obtainable and the chemical, thermal and corrosion resistance make Laser the main technology for high-level and indelible engraving applications over time.

Versatility

The possibility of working with a laser engraver on any type of material, the easy integration into systems and lines and the digital nature of the laser management process make it flexible to adapt to any application and suitable for highly customized products.

FREQUENTLY ASKED QUESTIONS

-

How much does a laser engraving machine cost?

The price of a laser engraving machine varies based on several factors: laser power, source...

The price of a laser engraving machine varies based on several factors: laser power, source type (CO₂, fiber, ultrashort pulse), working area dimensions, and automation level. Professional systems like those from EVLASER may have a higher cost compared to hobby-grade models, but offer significant returns through efficiency, precision, and durability. When considering the initial investment, it’s important to evaluate operating costs (energy consumption, maintenance) and compatibility with the materials to be engraved.

-

Which laser parameters affect engraving quality?

Engraving quality depends on the interaction between several process parameters: wavelength (which determines material absorption),...

Engraving quality depends on the interaction between several process parameters: wavelength (which determines material absorption), power density (W/cm²), pulse repetition frequency (kHz), and pulse duration (from nanoseconds to femtoseconds for ultrashort sources). The scanning speed of the galvanometers and the number of repetitions directly influence surface roughness and material removal. Additionally, control of the heat-affected zone (HAZ) is fundamental: with ultrashort pulses, thermal transfer to the substrate is minimized, avoiding microcracks or deformations. MOPA frequency modulation allows ablation optimization on materials with different damage thresholds.

-

How to choose a laser engraving machine?

When choosing a laser engraving machine, you need to consider: Type of material you want...

When choosing a laser engraving machine, you need to consider:

- Type of material you want to engrave (metals, glass, wood, leather, composites), because each laser source (CO₂, fiber, UV, MOPA) reacts differently on various materials.

- Engraving depth: whether you need deep engraving (multi-pass) or just surface marking.

- Speed and production: if you work on small batches or high volumes, you need a faster machine with more power or automation.

- Precision: if you need micrometric engraving (micro ablation), consider machines with high-quality galvanometers or ultrashort pulse (USP) sources.

- Total budget: not just the machine cost, but also energy consumption, maintenance, and possible integration costs (if using the machine on production lines).

-

How long does a laser engraving machine last?

The lifespan of a laser engraving machine depends largely on the source used and how...

The lifespan of a laser engraving machine depends largely on the source used and how it’s maintained. Well-managed quality sources can operate for many tens of thousands of hours. Proper maintenance (regular head cleaning, power monitoring, galvanometer checks) helps preserve system efficiency and reduce potential performance degradation over time.

-

What advanced industrial applications does laser engraving support?

Professional laser engraving enables specialized processes such as: Functional texturing: creation of periodic microstructures (LIPSS)...

Professional laser engraving enables specialized processes such as:

- Functional texturing: creation of periodic microstructures (LIPSS) to modify wettability, friction coefficient, or optical properties of surfaces

- Selective multi-layer ablation: controlled removal of coatings or thin layers (PVD, DLC) without damaging the underlying substrate

- Engraving on difficult materials: technical ceramics, reinforced composites (CFRP), high-performance alloys (Inconel, titanium Ti6Al4V), and semiconductors

- DataMatrix code marking: for industrial traceability according to UDI/DMC regulations with automated reading

- Laser micro-drilling: creation of holes with diameters below 50 µm on aerospace components, medical devices, and injectors

These applications require precise control of laser parameters and vision systems to ensure repeatability and compliance with industrial standards.