Industrial Vision Systems for precision Laser Applications

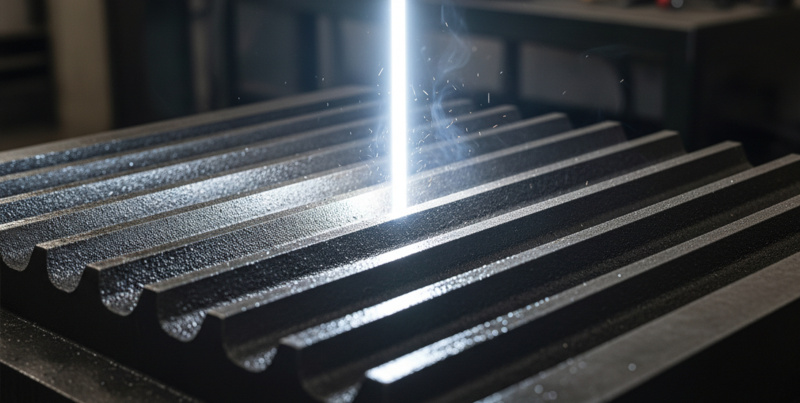

The integration of laser sources and advanced vision devices has revolutionized industrial marking and cleaning. Vision systems now ensure precision, repeatability, and quality control in laser processing, opening up application opportunities in the automotive, electronics, medical, and aerospace sectors.

Solutions that combine the power of the laser beam with the intelligence of industrial vision enable perfectly positioned markings, real-time verification, and selective cleaning processes on complex geometries.

What are Vision Systems and why they are strategic in laser processes

An industrial vision system combines hardware and software to acquire, process, and interpret visual information. In the laser context, these technologies perform three key strategic functions:

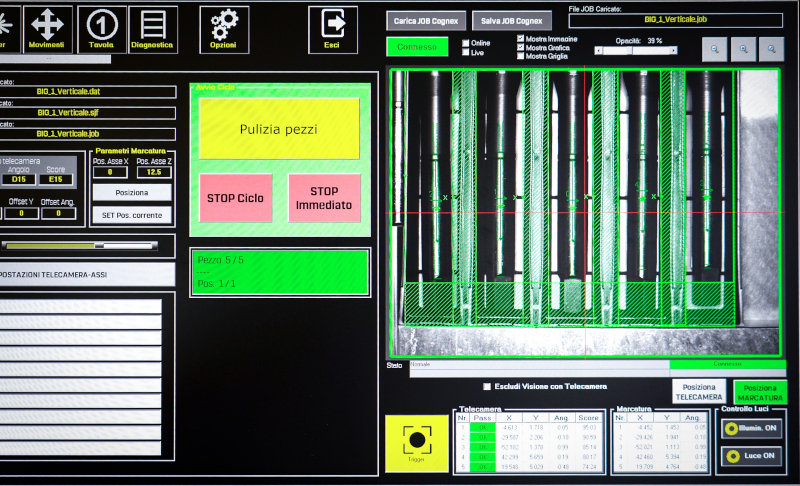

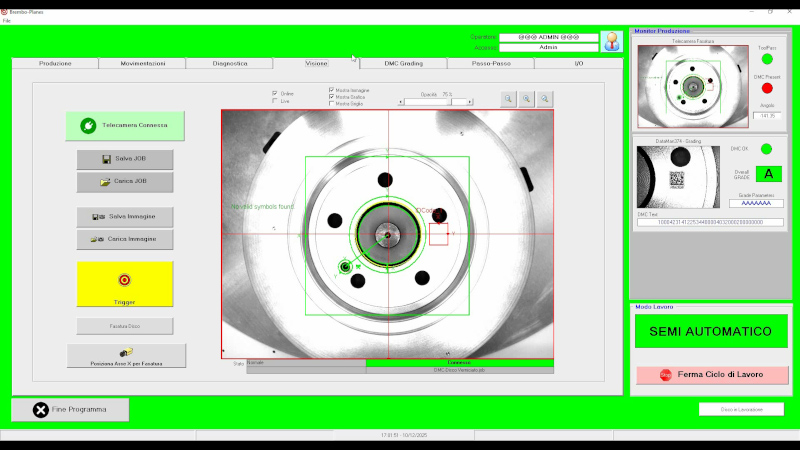

- Part centering via camera identifies the exact position of the component in the work area, compensating for positioning variations such as angle, rotation, and spatial location. This ensures laser marking at a precise point on the part, regardless of its placement on the table or handling system.

- Shape recognition through software analyzes the contours of the object using “edge detection” or processes the image pixel by pixel. The most advanced systems dynamically adapt the marking program to the detected geometry, making them advantageous when working with variable-shaped components or when laser marking must be performed relative to a specific reference.

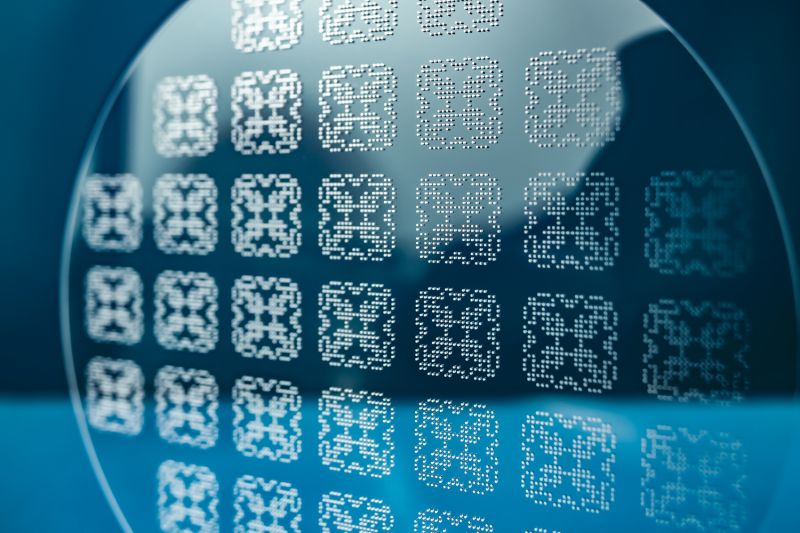

- Post-marking quality verification represents the third pillar. After processing, the vision system verifies the readability of DataMatrix or QR codes, checks contrast and sharpness, ensuring compliance with quality standards and drastically reducing scrap rates.

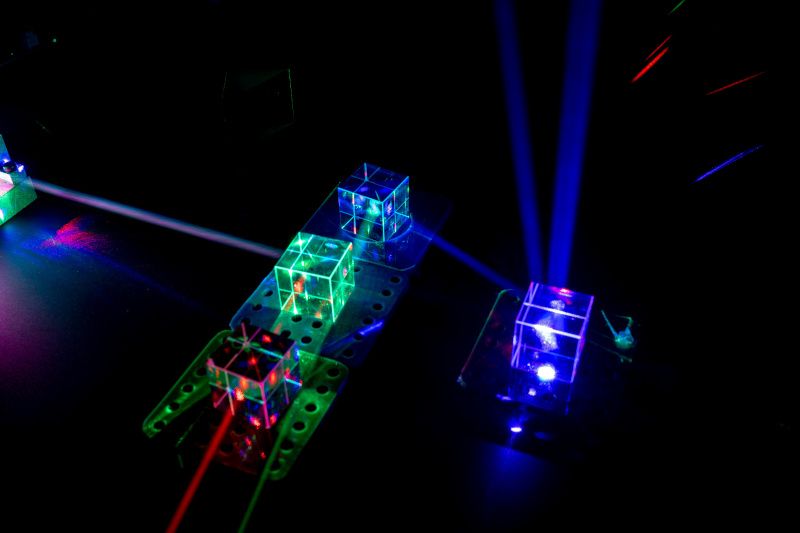

How Vision Systems work: components, image acquisition, and interpretation

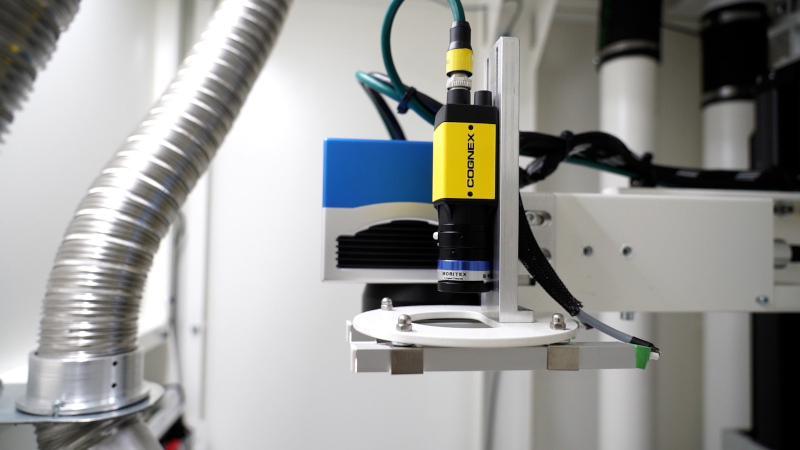

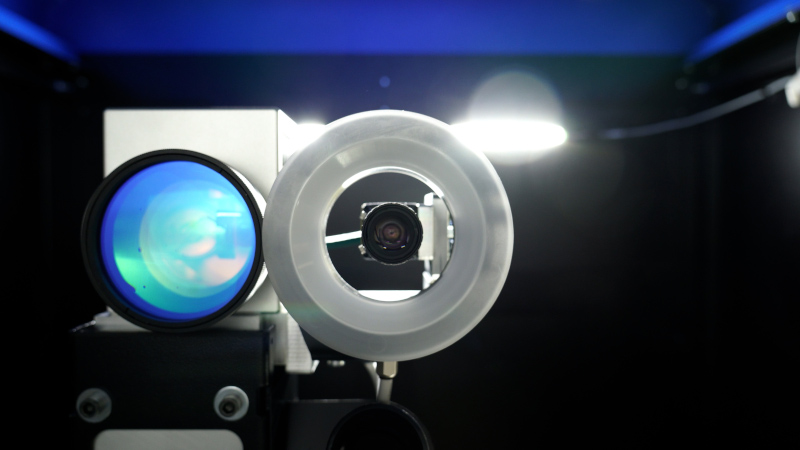

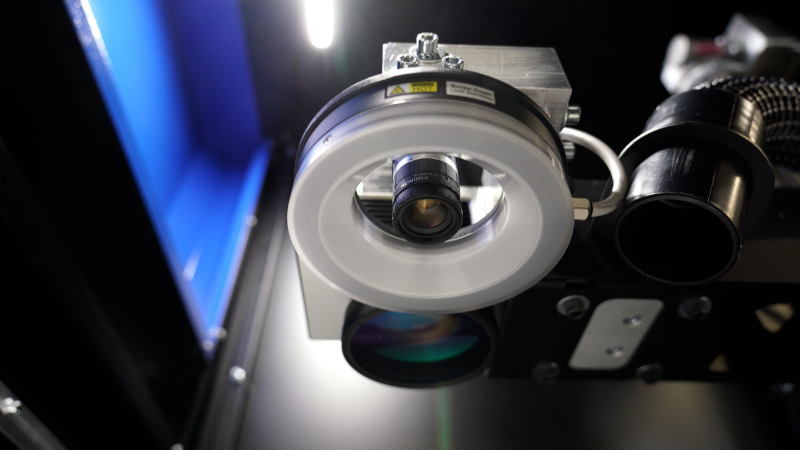

Understanding a vision system requires analyzing its core components and processing flow. At the center is the vision sensor, which can be CMOS or CCD.

CMOS cameras offer higher speed and lower power consumption, while CCD cameras guarantee excellent quality in critical conditions.

Lighting is a critical element in obtaining sharp images. Solutions include high-intensity LED lighting in coaxial or side configurations, up to structured lighting for three-dimensional detection. The optical system determines field of view, resolution, and depth of field.

The processing unit, implemented on industrial PCs, smart cameras, or embedded systems, hosts the algorithms that transform pixels into useful information.

The process is structured in sequential stages:

- image acquisition,

- pre-processing to improve quality,

- extraction of relevant information through machine vision algorithms,

- and communication of data to the laser control system.

This cycle is completed in tens of milliseconds, in line with high production rates.

Types of Industrial Vision Systems

2D Vision Systems

Two-dimensional vision systems represent the most widespread solution for laser marking on flat surfaces. They acquire planar images to extract information on object position, orientation, and features.

They offer high speed (hundreds of images per second), cost efficiency, and ease of integration, making them ideal for part centering, code reading, and shape recognition.

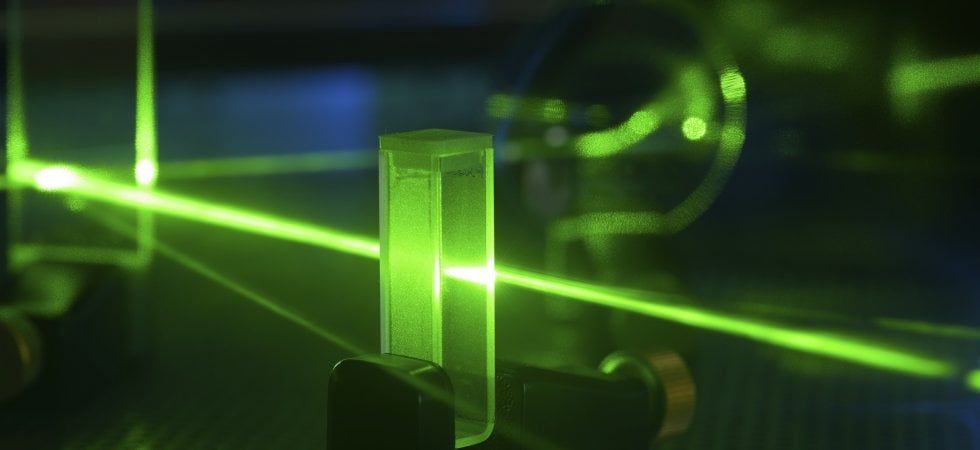

TTL and Side-Mounted Systems

TTL systems (Through The Lens) share the optical path between camera and laser: the camera acquires the image directly through the focal lens of the scan head from which the laser beam exits.

The field of view coincides with the marking area, eliminating parallax issues. Code reading takes place immediately after marking, with extremely precise centering.

Systems with a side-mounted camera provide wider fields of view, ideal for large components. The camera is mounted laterally with accurate calibration, allowing greater flexibility in lighting and inspection of extended areas.

Machine Vision Systems: Deep Learning and Adaptive Intelligence

Machine vision systems introduce learning capabilities that revolutionize complex laser applications. Unlike traditional algorithms based on predefined rules, they use machine learning and deep learning techniques to learn from image datasets.

Deep learning enables the software to learn to recognize shapes through training iterations. The operator provides examples of correct and defective parts in different orientations. The neural network analyzes these images, identifies distinctive features, and builds a model to classify new images.

This generalization capability makes it possible to handle lighting variability, tolerate geometric variations, and recognize partially occluded objects.

In the laser context, machine vision is applied to:

- automatic recognition of component type,

- AI-assisted quality verification that detects subtle defects,

- and adaptive centering on variable geometries.

For laser cleaning, it distinguishes the areas to be treated, adjusts parameters according to the contaminant, and verifies the result.

Implementation requires the creation of specific solutions: dataset collection, network architecture selection, training, and validation. Modern frameworks make it possible to complete this process in hours or days.

In critical applications, hybrid architectures are adopted, combining the robustness of deterministic algorithms with the flexibility of AI.

See Evlaser Solutions

Laser MarkingVision Systems for Robotics and Laser Automation

The integration of vision, robotics, and laser technology enables flexible work cells for variable-shaped components with minimal setup times.

Vision provides spatial information to locate, pick, and position components, guiding the robot to the exact marking or cleaning point.

Architectures include fixed cameras above the work area (eye-to-hand) or cameras mounted on the robotic arm (eye-in-hand). The former offers stability and simplified calibration, while the latter ensures flexibility to inspect from multiple angles.

In laser marking relative to a reference, the system identifies markers on the component, calculates position and orientation, and communicates the transformed coordinates to the robot. For complex geometries, the robot equipped with a laser head and vision navigates 3D surfaces, continuously adapting beam position and angle.

In laser cleaning, 3D vision mounted on the robot reconstructs the geometry, plans optimal trajectories, and verifies effectiveness in real time.

Synchronization requires industrial protocols such as Profinet or EtherCAT for data exchange with predictable latency.

Calibration of the integrated system determines the geometric relationship between camera, robot, and laser, transforming pixel coordinates into spatial coordinates.

Vision Systems for Quality Control in Laser Processing

Vision systems for quality control ensure high standards, reduce scrap, and implement data-driven continuous improvement.

After marking, they acquire an image of the marked code or text and evaluate its quality according to ISO/IEC standards.

For DataMatrix, contrast, cell uniformity, decodability, and absence of defects are verified, assigning a quality grade.

This inline verification inspects every component, ensuring traceability and immediate detection of drifts. If quality deteriorates due to optical wear or focus variations, the system detects the issue by triggering alarms or automatic adjustments.

For critical applications (medical, aerospace), multi-stage systems are implemented to verify the component before, during, and after marking.

In laser cleaning, control evaluates contaminant removal effectiveness, verifies treatment uniformity, and checks that the substrate has not been damaged.

See Evlaser Industrial Systems

Laser CleaningHow much do Vision Systems for Laser Applications cost?

Understanding cost factors enables informed technological choices and investment optimization.

Entry-level 2D systems with smart cameras, standard resolution, and basic algorithms start at €3,000–5,000, suitable for simple applications.

Mid-range systems with high-resolution cameras, optimized lighting, and advanced algorithms range between €8,000–15,000, offering greater flexibility and precision.

Key determining factors include:

- Camera resolution: sensors above 10 megapixels cost thousands of euros more than VGA,

- Acquisition speed: high-speed cameras are significantly more expensive,

- Lighting: from standard LEDs to high-intensity coaxial systems (€1,000–5,000 additional),

- Integration: systems integrated by the laser manufacturer have a premium price but offer higher reliability,

- Software: licenses ranging from €1,000 to €10,000 depending on functionality.

The return on investment considers scrap reduction, increased productivity, elimination of manual operations, and improved traceability. The payback period is often less than 12–18 months.

Integrated solutions and convergence: a look at the future

Vision systems have transformed laser marking and cleaning applications into integrated solutions capable of ensuring quality, autonomy, traceability, and flexibility.

The convergence of traditional industrial vision, artificial intelligence, and robotics opens up increasingly sophisticated application scenarios to address complex production challenges.

Choosing the appropriate system requires careful analysis of specific application requirements, balancing technical needs, economic constraints, and long-term objectives.

In this scenario, the integration between laser and vision systems is not a simple technological option, but a key design element for implementing reliable, scalable, and quality-oriented industrial solutions.