The new era of Mold Cleaning: Laser solutions for high-precision Industry

In the modern industrial context, mold maintenance represents a crucial element for ensuring production quality and operational efficiency.

Laser mold cleaning has established itself as a revolutionary technology, overcoming the limitations of traditional methods through a non-invasive, precise, and environmentally sustainable process.

This advanced solution meets the growing demands for quality, speed, and environmental responsibility that characterize high-precision manufacturing industries.

What is Laser Mold Cleaning

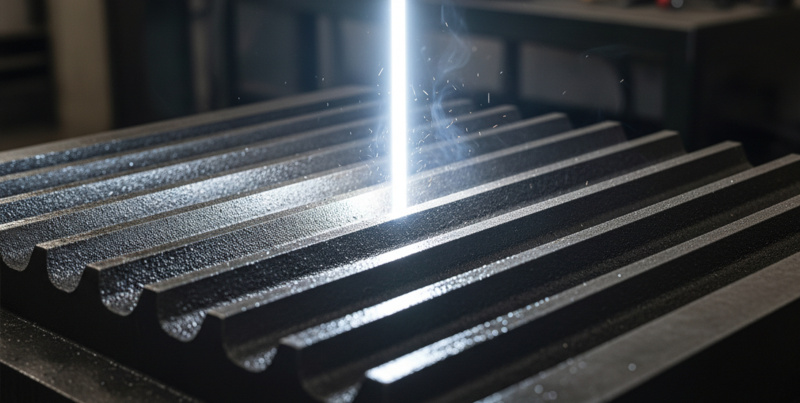

Laser mold cleaning is a technological process that uses a high-intensity laser beam to remove surface contaminants without any physical contact with the mold.

The principle is based on the controlled emission of light pulses that selectively interact with the unwanted material layer, causing its vaporization or thermal ablation.

Unlike conventional methods, this technique acts exclusively on the residues to be removed, fully preserving the integrity of the underlying mold surface.

The process makes it possible to remove a wide range of contaminants:

- production residues such as vulcanized rubber or plastic polymers,

- silicone release agents,

- surface oxidation,

- industrial oils and greases,

- as well as ink deposits in the printing industry.

The ability to precisely adjust laser parameters allows the treatment to be adapted to the specific characteristics of each material and type of contamination, ensuring optimal results in every situation.

How Laser Mold Cleaning Works

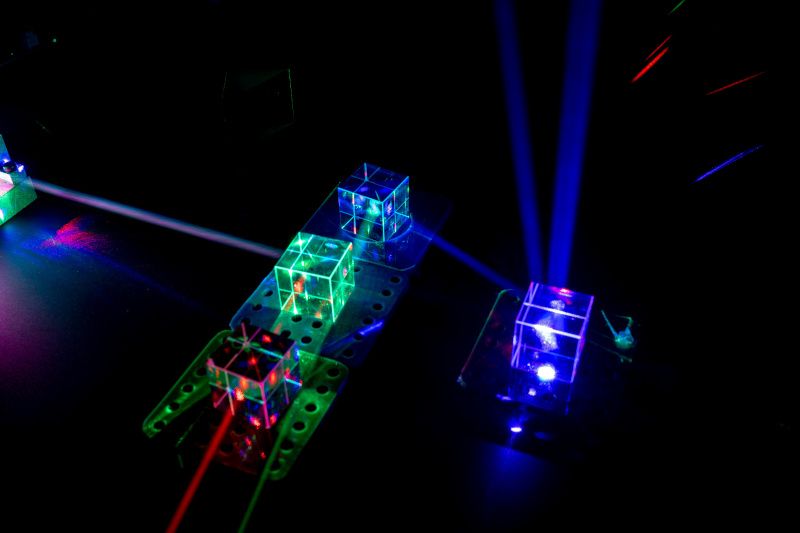

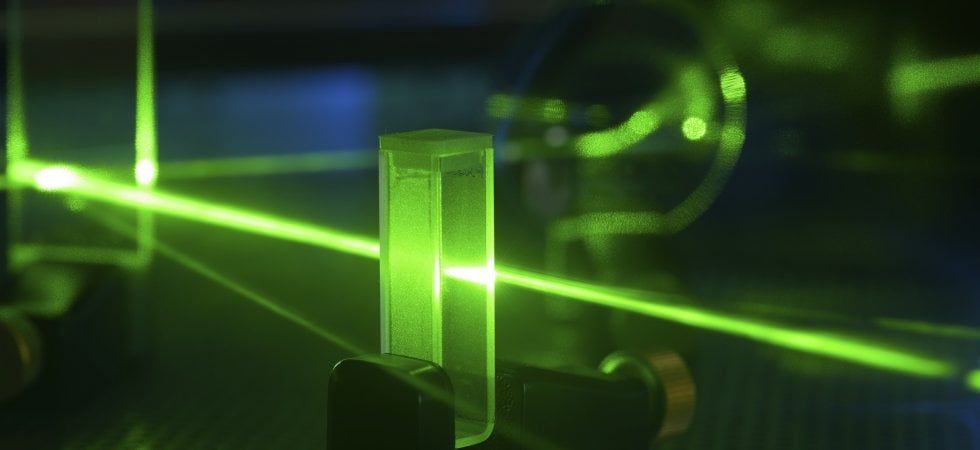

The operation of laser technology for mold cleaning is based on a well-defined physical principle. The laser beam, generated by fiber laser sources or high-energy pulsed lasers, is focused on the surface to be treated through a high-precision optical system.

Light energy is absorbed differently by the materials present: surface contaminants, generally characterized by optical and thermal properties different from those of the metal substrate, absorb laser radiation more efficiently.

This selective absorption generates rapid localized heating, leading to the decomposition, vaporization, or sublimation of the unwanted material. The process takes place in fractions of a second, with laser pulses lasting microseconds or nanoseconds, minimizing heat transfer to the underlying mold.

The vaporized residues are immediately captured by an integrated extraction system, ensuring a clean and safe working environment.

Modern technology enables the use of galvanometric scanning heads that move the laser beam at extremely high speeds, efficiently covering even complex surfaces.

In the most advanced systems, the laser head can be mounted on six-axis anthropomorphic robots, enabling automated cleaning of three-dimensional geometries and hard-to-reach areas with millimetric precision.

See Evlaser Solutions

Laser CleaningAdvantages of Laser Mold Cleaning

Mold cleaning using laser technology offers numerous advantages over traditional methods, representing a strategic investment for companies focused on manufacturing excellence.

Environmental sustainability

The ecological impact of industrial laser mold cleaning is significantly lower than that of conventional techniques. No chemical solvents, aggressive detergents, or abrasive materials are used, which would otherwise require costly disposal as hazardous waste.

The only consumables involved are the filters of the extraction system, which capture vaporized particles. This feature completely eliminates the production of contaminated wastewater typical of chemical and ultrasonic cleaning, drastically reducing the environmental impact of production activities and facilitating compliance with increasingly stringent environmental protection regulations.

Energy consumption is another major advantage: a 300-watt laser machine typically draws about 2 kilowatts, a value significantly lower than that of traditional cleaning systems requiring heated chemical baths or high-power compressors for sandblasting.

Operational advantages over traditional methods

Comparing laser cleaning with conventional systems reveals substantial differences in terms of efficiency and quality. Chemical and ultrasonic cleaning, while delivering acceptable results, involve long process times, high operating costs related to maintaining optimal chemical levels and controlled temperatures, and complexities in handling aluminum molds.

Traditional sandblasting, although effective in mechanical removal, causes tool wear, consumes abrasive materials, and can result in micro-surface damage that compromises mold roughness.

Dry ice blasting is a gentler alternative but requires a continuous supply of solid CO₂, powerful compressors, and is primarily effective on hot molds, limiting its versatility.

Manual cleaning, still widespread in many settings, exposes operators to health risks and involves extended operating times with inconsistent results.

Laser technology completely eliminates these drawbacks: it requires no consumables, operates without physical contact while perfectly preserving surface characteristics, demands virtually no maintenance, and ensures consistent, repeatable results over time.

Processing speed is significantly higher, enabling a substantial reduction in machine downtime and an increase in overall productivity. Operators work in safe conditions, without exposure to harmful chemicals or physically demanding tasks.

Materials and applications

The versatility of laser mold cleaning makes it suitable for a wide range of materials and industrial sectors, each with specific technical requirements.

Laser Cleaning of Plastic Molds

Plastic mold cleaning is one of the most widespread applications of laser technology. Molds used in the plastics processing industry accumulate polymer residues, release agents, and process oils that compromise the quality of molded parts.

The laser effectively removes these contaminants without altering the surface roughness of the mold, a critical factor for ensuring proper part release and surface finish quality.

Laser cleaning preserves the extremely tight dimensional tolerances required by injection molds, preventing defects in finished products and promoting better heat transfer during the molding cycle.

Laser Cleaning of Tire Molds

In the tire industry, rubber mold cleaning is a particularly challenging application. Vulcanization molds accumulate vulcanized rubber residues, organic and inorganic compounds, as well as carbonized deposits formed during high-temperature processes.

Laser technology, especially in advanced robotic systems, allows for the thorough cleaning of even complex tire mold geometries, including venting channels and spring vents that ensure air evacuation during vulcanization.

Innovative systems integrate laser cleaning with resonance modulators that, by identifying the mold’s natural frequency, generate vibrations that facilitate the removal of residues from the most difficult-to-access channels.

Laser Cleaning of Industrial Containers and Food Molds

In the food industry, hygiene standards are an essential requirement. Laser cleaning is applied to the decontamination of baking trays, pans, conveyor belts, and molds used in food production.

The technology ensures complete removal of organic residues, fats, and contaminants without the use of chemical products that could leave unwanted traces. Treated surfaces are perfectly clean and immediately reusable, without the need for drying or additional treatments.

This feature also makes laser cleaning particularly suitable for the pharmaceutical sector, where surface sterility and purity are critical.

Automated Laser Cleaning with Robots

Technological evolution has led to the development of fully automated systems that integrate laser cleaning with industrial robotics. Six-axis anthropomorphic robots equipped with digitally controlled laser heads enable complete automation of the mold cleaning process.

These systems use 3D vision technologies to map mold geometry, create customized cleaning recipes, and ensure process repeatability. Integrated artificial intelligence monitors cleaning effectiveness and flags areas requiring special attention.

Robotic laser cleaning cells are the ideal solution for high-volume production with frequent product changeovers, allowing molds to be processed in masked time relative to production.

Integration with corporate information systems enables full traceability of maintenance operations, supporting predictive planning and optimization of cleaning cycles.

M² and Depth of Field in Industrial Laser Mold Cleaning

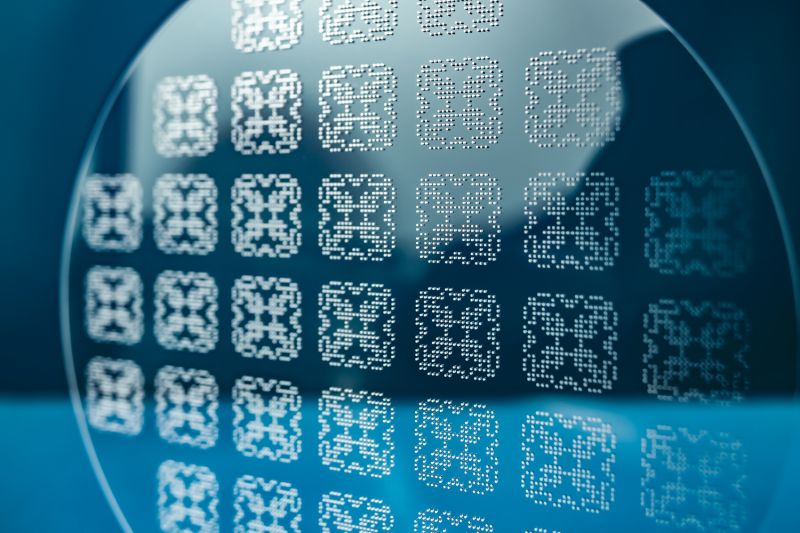

In industrial laser mold cleaning, the M² parameter determines the precision and effectiveness of the decontamination process. This value indicates the optical quality of the laser beam compared to an ideal profile (M² = 1).

Low M²: precision for complex geometries

For laser mold cleaning, systems with low M² values (1 < M² < 2) offer decisive advantages:

- Access to deep cavities: a smaller laser spot reaches difficult areas and intricate details,

- Selective cleaning: precise removal of release agents, rubber residues, plastic, and carbonized deposits without damaging mold surfaces,

- Preservation of micro-textures: accurate focusing protects critical surface finishes,

- Removal of transparent contaminants: effective on oils, greases, and organic residues that often contaminate molds.

High M²: productivity for large surfaces

For large molds with extensive areas to be treated, higher M² values allow:

- Reduced cycle times: rapid coverage of large, flat surfaces,

- Increased productivity: ideal for scheduled maintenance of large-format molds.

Energy Density in Molds

Effective removal of typical mold contaminants (vulcanizing agents, silicone release agents, polymer residues) requires exceeding specific ablation thresholds.

With higher M² values, it is essential to ensure that energy density remains sufficient even at the operating speeds required by the production cycle.

The choice of the optimal laser system for mold cleaning depends on:

- Mold geometry: deep cavities require low M² values,

- Type of contaminant: stubborn residues require high energy density,

- Production volume: cycle times influence the ideal configuration.

Our laser mold cleaning systems make it possible to test different configurations to identify the perfect balance between cleaning quality, mold preservation, and process productivity.

Read More

Rust Removal with LaserIndustrial Sectors of Application

Laser mold cleaning is used across numerous industrial sectors, each with specific requirements and characteristics.

The automotive sector is one of the main areas of application. Molds for plastic components such as dashboards, tanks, lighting systems, and engine parts require frequent maintenance to ensure consistent production quality. Laser cleaning keeps molds in optimal condition without prolonged downtime, supporting the high production rates typical of the sector.

The tire industry has adopted laser technology as a standard for vulcanization mold maintenance. The ability to effectively clean complex geometries and venting channels while preserving perfect tread reproduction represents a significant competitive advantage.

In the packaging and printing sector, laser cleaning is used for maintaining anilox rollers in flexographic printing machines, where precise removal of residual inks ensures consistent print quality and prevents color contamination.

The electronics industry uses laser cleaning for mold maintenance and for precision cleaning of critical components such as electrical contacts, where surface purity and absence of contamination are essential.

The medical and pharmaceutical sector benefits from laser cleaning in the maintenance of molds for medical devices and in the sterilization of containers and production surfaces, where hygiene standards are particularly stringent.

Sectors such as aerospace, precision mechanics, industrial glass, and technical rubber have also integrated laser technology into their maintenance processes, recognizing its benefits in terms of quality, efficiency, and cost-effectiveness.

Read More

Laser DecoatingHow much does Laser Mold Cleaning Cost

The economic evaluation of laser mold cleaning requires an analysis that considers both the initial investment and medium- to long-term operating costs.

The initial investment for a laser cleaning system varies depending on power, technological features, and level of automation.

Low-power portable machines, ideal for limited applications or small workshops, are priced from approximately €7,000–10,000 for 100-watt systems.

Medium-power solutions, between 300 and 500 watts and more suitable for continuous industrial use, typically range between €20,000 and €40,000.

High-power systems, 1,000 watts and above, used in intensive production environments, can require investments of €60,000–80,000.

Fully automated robotic cells represent the top end of the market, with costs starting from €40,000 for basic systems and exceeding €150,000 for advanced industrial configurations with anthropomorphic robots, 3D vision systems, artificial intelligence, and full integration with corporate systems.

However, economic analysis must consider the total cost of ownership. Laser systems feature extremely low operating costs: reduced energy consumption, no consumables other than extraction filters, and virtually no maintenance. Modern laser sources have operational lifetimes exceeding 100,000 hours, equivalent to several years of intensive industrial use without replacement.

Compared to traditional methods, process costs are significantly lower.

Chemical systems require continuous purchase of detergents, maintenance of operating temperatures, wastewater disposal, and involve long processing times. Sandblasting requires large quantities of abrasive materials, with associated procurement and disposal costs. Dry ice cleaning demands a constant supply of solid CO₂ and powerful compressors with high energy consumption.

The return on investment for a laser system is typically achieved within 2–4 years of industrial use, considering savings on consumables, reduced machine downtime, improved production quality, and longer mold life due to non-invasive cleaning. For high-volume production with frequent cleaning, ROI can be achieved even faster.

Laser technology therefore represents not only an investment in technological innovation, but a cost-effective choice that combines operational efficiency, superior quality, and environmental sustainability, increasingly critical factors in today’s competitive industrial landscape.